Production processes are getting harder day by day. Challenging production needs more speed, more pressure and extreme temperatures. With the improvement of materials science, the material variety is enlarging like composites, nickel and cobalt. Besides performance and cost effective processes to assure healthy work place and environment needs well managed metal working fluids.

Besides our technical trainings about products and application we also serve with critical analysis in the production sites.

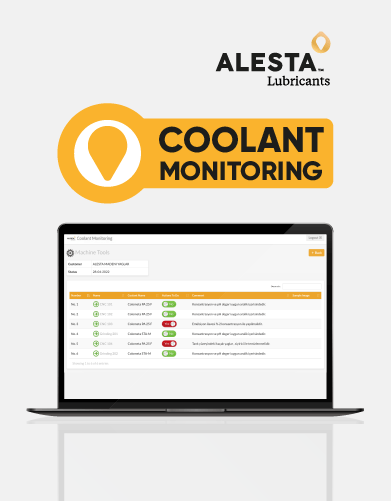

In Alesta Coolant Monitoring System, your machine park, products and technical data are defined specially for your plant. With different user identifications team organization is easy. Dynamic reports provide effective data analysis and planning. Onfield analysis and laboratory measurements are recorded to Alesta Coolant Monitoring System. Time dependent trend reports are available. To-do actions can be givem from Alesta and be followed together. Alesta Coolant Monitoring System is easy-to- use due to user friendly design and mobile compatibility.

Systematic application of Coolant Monitoring System assures unplanned machine stops, work loss and consumption. Low wastes assures clean and healthy environment.

Alesta Coolant Monitoring System lowers the total cost and increases the productivity.